MPN: 23280

3/4" Press X 1/2" MPT Male Adapter CopperPress Press Fitting

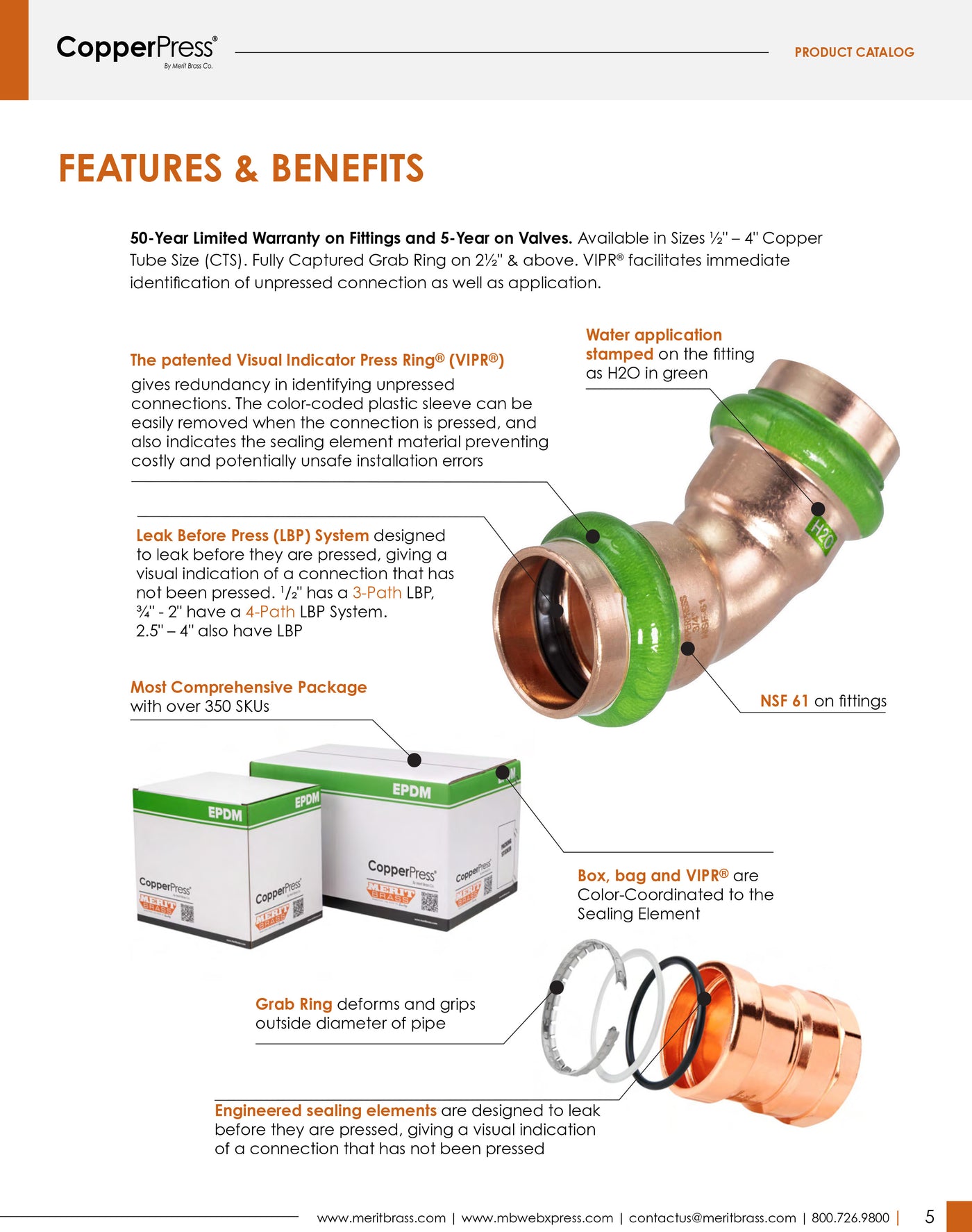

- Visual Indicator Press Ring (VIPR) – facilitates immediate identification of un-pressed connections

- Leak Before Press – in addition to the VIPR, valve incorporates four path LBP technology,guaranteeing a visual indication if not pressed

- Permanent Application Marking – imprinted on fitting body for quick H2O or gas application identification

- Lead Free Construction – fully compliant with current lead-free laws

- Copper Ends - protect against dezincification and stress corrosion cracking

3/4" Press X 1/2" MPT Male Adapter CopperPress Press Fitting is backordered and will ship as soon as it is back in stock.

Pickup available at Nordik Radiant

Usually ready in 2-4 days

Warranty

Warranty

This product is covered by a 50 years limited warranty

Delivery and Shipping

Delivery and Shipping

Orders are shipped within 2 business days. If a problem prevents us from shipping your order within this time, we will notify you.

Depending on your delivery location, transit time will vary from 1 day to 5 days.

Note for US and Internationnal buyers: The customer is responsible for paying any import costs to the shipping carrier, such as duties, import taxes, or brokerage/disbursement fees that may apply upon delivery.

3/4" Press X 1/2" MPT Male Adapter CopperPress Press Fitting is backordered and will ship as soon as it is back in stock.

3/4" Press X 1/2" MPT Male Adapter CopperPress Press Fitting

CopperPress Presentation

Frequently Asked Questions about CopperPress fittings

How does a CopperPress® fitting seal?

How does a CopperPress® fitting seal?

A special tool physically “presses” the fitting onto the tube creating a mechanically sound

joint. Hydraulic tightness is insured by an o-ring seal.

How does a press fitting compare to other joining methods?

How does a press fitting compare to other joining methods?

Simply put, press fit technology allows tubes to be joined mechanically without threading

or soldering. This means no solvents, thread sealants, or open flames are required.

Pressing is a comparably fast joining method requiring less technical skill to install than

other means. Press installations typically costs 30% - 50% less than those made with

other joining methods due to labor and auxiliary material savings, and the joints made are

clean and professional looking every time.

What type of tubing should be used with CopperPress® fittings?

What type of tubing should be used with CopperPress® fittings?

CopperPress® fittings are designed to be used with ASTM B88 Type K, L and M copper

tubing in the hard-drawn condition ½” – 4” and soft copper tubing in sizes ½" to 1¼"

Where can CopperPress® fittings be used?

Where can CopperPress® fittings be used?

Anywhere traditional copper fittings are used – plumbing and heating, hot, chilled and

process water systems, and commercial or industrial applications where gas, low

pressure steam, or liquids are conveyed.

What type of CopperPress® fittings does Supply Source Products offer?

What type of CopperPress® fittings does Supply Source Products offer?

Supply Source Products provides a complete line of copper press fittings including

adapters (male, female, street, pex and flange), couplings with and without stops,

reducers, elbows, tees (equal and reducing), drop ear elbows, end caps, cross overs, and

unions in sizes ½” – 4”. As a matter of fact, we carry a like for like product line nearly

identical to the market leader.

Can I install CopperPress® fittings in a wet (charged) system?

Can I install CopperPress® fittings in a wet (charged) system?

CopperPress® fittings can be installed in wet or dry systems, however system pressures

should be relieved to avoid injury prior to installation. Being able to make a repair without

a complete system drain is a huge advantage.

What are CopperPress® fittings made of?

What are CopperPress® fittings made of?

Our fittings are constructed of lead-free copper or brass and are in compliance with

NSF/ANSI/CAN 61.

How can I be assured a joint has been pressed in an installation?

How can I be assured a joint has been pressed in an installation?

In addition to a mechanical leak before press feature, CopperPress® fittings feature a

colored band that not only provides a visual indication of the o-ring material (green for

H2O and yellow for gas), but also alert the installer of an un-pressed connection condition.

When pressed, the band falls away.

Why should I use press products instead of those joined by traditional methods(soldering, brazing, welding, threading, etc.)?

Why should I use press products instead of those joined by traditional methods(soldering, brazing, welding, threading, etc.)?

Press connections can be made in the fraction of the time required by other joining

methods, and no open flame or flame permit is required. Faster installations translate

into significant labor savings. Connections made by pressing are sound, simple, and

clean and provide an economical alternative to other means of joining tube.

Are press connections secure?

Are press connections secure?

Absolutely. Press connections made per Supply Source Product’s recommended

practice are as secure as any other joining method. Press technology has a multi-decade

track record of successful installations all across the world.

How long does it take to make a press connection?

How long does it take to make a press connection?

A press connection can be made in less than a minute with preparing the tube taking 30

seconds or less (deburring and marking insertion depth) and the actual pressing only a

few seconds – literally the time it takes to insert the tube and cycle the tool. Unlike other

methods full structural integrity and sealing capability is realized immediately

Can a joint be adjusted after pressing?

Can a joint be adjusted after pressing?

Slight torsional adjustments (generally 5 degrees or less) can be made after pressing.

More significant rotations require that the joint to be repressed.

What press tools should I use when making CopperPress® press connection?

What press tools should I use when making CopperPress® press connection?

CopperPress® fittings can be pressed with Milwaukee, REMS, Rigid and Rothenberger

tools and associated CTS jaws. Contact Supply Source Products’ Customer Service for

specific jaw set compatibility

What are the pressure and temperature ranges of CopperPress® fittings?

What are the pressure and temperature ranges of CopperPress® fittings?

CopperPress® fittings have a working pressure and temperature range of 0 - 300 psi and

0 - 250°F respectively on ASTM B88 Type K, L and M copper tubing in the hard-drawn

condition and soft copper tubing in sizes ½" to 1¼".

Which o-ring should I select?

Which o-ring should I select?

CopperPress® fittings are available with an EPDM o-ring for water applications and

HNBR o-ring for gas applications. Contact Supply Source Products’ Customer Service

for specific chemical compatibility.

What pipe hanger and support requirements should my installation follow?

What pipe hanger and support requirements should my installation follow?

Support hanger spacing should correspond to the ASME B31.1 Power Piping Code,

ASME B31.3 Process Piping Code, or ASME B31.9 Building Services Piping Code as

appropriate. Consult the local authority having jurisdiction for possible additional

requirements. Proper bearing and spacing of supports are necessary to prevent

excessive bending or sagging. The weight of the conveyed material should also be

considered.

Are dilectric unions necessary when joining dissimilar metals?

Are dilectric unions necessary when joining dissimilar metals?

Yes. Using a dilectric union is a recommended practice. When too dissimilar metals (like

copper and iron) come into contact in the presence of an electrolyte like water, an

electrical current will flow between the two and the more anodic metal, in this case the

iron, will corrode more quickly than it would if not coupled, and can ultimately lead to joint

failure. This type of failure is often seen in water heater applications. A dilectric union

separates the two metals with a gasket, preventing the current flow and resulting galvanic

corrosion.